Navigating Injection Molding Vendors in China

So, the big meeting just wrapped up. your new project has the green light, the schedule is tight, and the budget is, let’s say, constrained.. And suddenly someone—perhaps your superior or the finance head—says the fateful words that make any project manager’s heart skip a beat: “We should look at sourcing this from China.”

Naturally, you agree. It seems sensible at first glance. The potential savings can be massive. However, your brain is racing with concerns. You know the rumors, don’t you? The nightmare of defective parts, opaque communication, and delayed, off-spec shipments. It’s like balancing on a tightrope between a massive cost advantage and project disaster.

However, here’s the reality. Sourcing plastic mold company doesn’t have to be a gamble. It’s simply another project with clear steps. And like any project, it succeeds or fails based on the process you follow. It isn’t about the cheapest offer but about choosing the right supplier and running the process transparently. Ignore the nightmare anecdotes. Let’s go through a step-by-step guide to succeed.

Step One: Do Your Homework

Before you even whisper the word “supplier” or open a browser tab to Alibaba, you need to get your own house in order. In fact, most overseas manufacturing headaches stem from a vague or incomplete RFQ. Don’t assume a remote factory can guess your needs. A vague RFQ is like telling a contractor to bid on “a house.” The responses you get will be all over the map, and none of them will be useful.

Your goal is to create a Request for Quotation, or RFQ, package that is so clear, so detailed, that it’s nearly impossible to misinterpret. It’s the cornerstone of your entire effort.

What belongs in your RFQ?

Begin with 3D CAD models. They’re essential. Provide files in common formats (e.g., STEP, IGS) to prevent import issues. This is the authoritative CAD geometry.

But 3D isn’t enough. Add comprehensive 2D plans. This details critical info missing from the 3D file. Think tolerances, material grades, finish specs, and any feature-critical notes. If a specific surface needs to be perfectly smooth for a seal, or a particular hole diameter is vital for an assembly, your 2D drawing needs to shout it from the rooftops.

Then specify the material. Avoid generic terms like “Plastic.” Nor just “ABS.” Get precise. If you need SABIC Cycolac MG38 in black, say exactly that. What’s the reason? Because there are thousands of plastic variations. Specifying the exact resin grade ensures you get the strength, flexibility, UV resistance, and color consistency you planned for with what is plastic mold.

A good supplier can suggest alternatives, but you need to give them a clear starting point.

Don’t forget the commercial info. What’s your forecasted annual volume (EAU)? They need clarity: is it 1,000 total shots or a million units per annum? The tool design, the number of cavities, and the price per part all hinge on this number.

Hunting for the Best Supplier

With your RFQ perfected, now, who do you send it to? Online sourcing is global but crowded. Locating vendors is easy; vetting them is the real challenge.

Your search will likely start on platforms like Alibaba or Made-in-China.com. They offer breadth but not depth. Treat them as initial research tools, not final solutions. Narrow your pool to about a dozen promising firms.

However, don’t end your search there. Perhaps hire a local sourcing specialist. True, they charge a fee. But a good one has a vetted network of factories they trust. They handle local liaison and oversight. As a newcomer, this offers priceless security. It’s schedule protection.

Another tactic: trade exhibitions. If you can attend, shows such as Chinaplas transform sourcing. In-person meetings trump emails. You can handle sample parts, meet the engineers, and get a gut feeling for a company in a way that emails just can’t match. Also, leverage the tried-and-true referral network. Ask other project managers in your network. Peer endorsements carry huge weight.

Sorting the Contenders from the Pretenders

With your RFQ dispatched to dozens of firms, bids begin to arrive. You’ll see ridiculously low offers and steep quotes. Your job now is to vet these companies and narrow it down to two or three serious contenders.

How do you do that? It blends technical checks with intuition.

Step one: audit communication. Are their replies prompt and clear? Is their English good enough for complex technical discussions? But the key: do they probe your RFQ? A great supplier will review your RFQ and come back with thoughts. Example: “Should we add draft here for better ejection?” or “Your tolerance may require extended CMM time—okay?” This is a massive green flag. It shows they’re engaged and experienced. Anyone who simply agrees to all specs is a red flag.

Then confirm their machinery specs. Get their tooling inventory. Review examples of parts akin to your design. A small-gear shop won’t cut it for a big housing.

Then comes the audit. Skipping this is a mistake. As you vet staff, you must vet suppliers. Either visit in person or engage a local audit service. They’ll send a local inspector to the factory for a day. They will verify the company is real, check their quality certifications like ISO 9001, assess the condition of their machinery, and get a general feel for the operation. It’s the best few hundred dollars you will ever spend on your project.

From Digital File to Physical Part

After picking your vendor, you agree on 50% deposit to start toolmaking and 50% balance after sample sign-off. Then comes the real action.

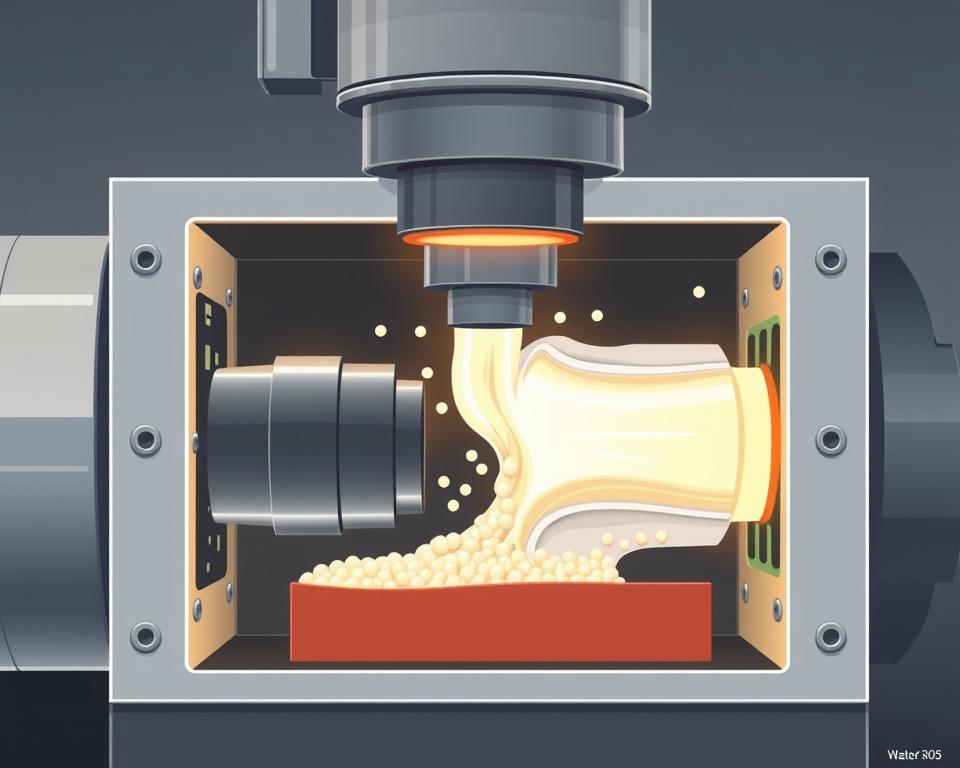

The first thing you should get back after sending your payment is a DFM report. DFM means Design for Manufacturability. It’s their professional review of your CAD. It will highlight potential issues like areas with thick walls that could sink, sharp corners that could cause stress, or surfaces without enough draft angle for clean ejection from the mold. A thorough DFM is a sign of a professional operation. It becomes a joint effort. You work with their engineers to refine the design for optimal production.

When you greenlight the DFM, they machine the mold. A few weeks later, you’ll get an email that will make your heart beat a little faster: “T1 samples have shipped.” These are the very first parts off the new tool. It’s your first real test.

Expect T1s to need tweaks. This is normal! There will be tiny imperfections, a dimension that’s slightly out of spec, or a blemish on the surface. You’ll provide detailed feedback, they’ll make small adjustments (or “tweaks”) to the tool, and then they’ll send you T2 plastic mold company samples. This process might take a couple of rounds. Plan for this loop in your schedule.

Eventually, you will receive a part that is perfect. It meets every dimension, the finish is flawless, and it functions exactly as intended. This becomes the “golden sample.” You ratify it, and it becomes the quality yardstick for production.

Crossing the Finish Line

Receiving the golden sample seems like victory, but you’re not done. Now you’re entering the mass production phase. How can you keep part #10,000 matching your golden sample?

You need a clear Quality Control plan. This often involves a pre-shipment inspection. Use a third-party inspector again. They’ll sample parts, check dimensions and finish versus your drawings and golden sample, and report. You receive a full report with images and measurements. After your approval, you release the shipment and final funds. This simple step prevents you from receiving a container full of scrap metal.

Lastly, plan logistics. Know your shipping terms. Does FOB apply, passing risk at the ship’s rail? Or EXW, shifting all transport to you? These choices hugely affect landed cost.

China sourcing is a long-haul effort. It’s about building a relationship with your supplier. View them as allies, not vendors. Clear communication, mutual respect, and a solid process are your keys to success. No question, it’s demanding. However, armed with this guide, you’ll secure savings and keep high standards intact. You’re set to succeed.